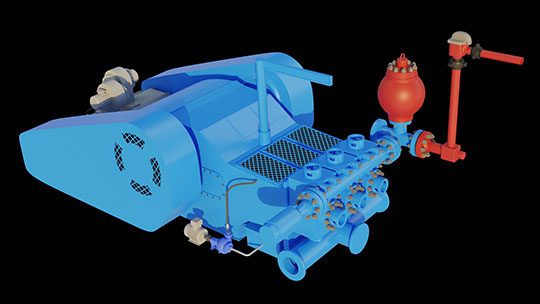

Mud Pump

Leave a CommentMud Pump

Centrif is one of the major suppliers for Mud pump and mud pump spares that include but not limited to the below:

- Consumables (liner, valves, pistons, disc, seat and all other consumables)

- Capital spares (Entire fluid end, power ends, manifold, crankshaft, frame, gear, pump, connecting rod etc)

- Full Mud pump skids and packages too based on client requirements.

- Cementing unit spares

Centrif have supplied all types of spares and provided services to major operators including high critical services from installation to commissioning.

Complete services right from Design, Engineering, Manufacturing, Quality, Testing, Field Services, Spare part supply, Troubleshooting, Retrofitting, Reliability Improvement Programs, Reverse engineering (Re-engineering), Installation, Commissioning and Training is provided.

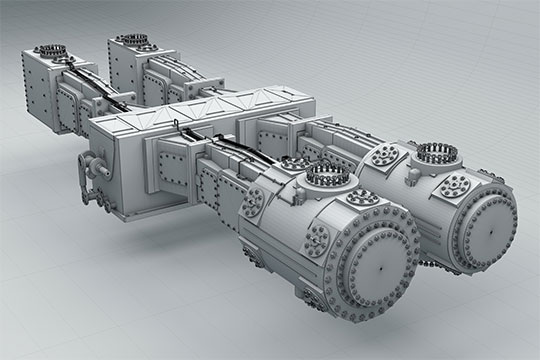

Reciprocating compressor

Leave a CommentReciprocating compressor

Centrif is one of the major suppliers for all Reciprocating compressor parts that include but not limited to the below:

- Consumables (Rider band, Piston ring, Valves, Gaskets, Rings, scrapper etc)

- Gas end spares (Crosshead, crosshead shoe, liner, piston nut, packing etc)

- Crank end spares (Connecting rod, bearings, lube oil pump etc)

- Capital spares (Crankshaft, frame, cooling water pump, cylinder, distance piece, flywheel, piston, piston rod etc)

Centrif have supplied all types of spares and provided services to major operators including high critical services from installation to commissioning.

Complete services right from Design, Engineering, Manufacturing, Quality, Testing, Field Services, Spare part supply, Troubleshooting, Retrofitting, Reliability Improvement Programs, Reverse engineering (Re-engineering), Installation, Commissioning and Training is provided.

Reciprocating Pump

Comments Off on Reciprocating PumpReciprocating Pump

Centrif is an Original Equipment Manufacturer (OEM) which designs, manufactures and provide solutions based on API 674 with the most robust and reliable design in market. Centrif have a full spectrum support from design to after sales support 24×7.

Centrif support with Complete Design and Engineering support including Pulsation studies on piping (design approach 1 and 2 according to API 674 code), Stress and fatigue analysis and Reliability assessment with our inhouse specialists. Centrif provide pumps that meets requirements with high performance and accurate volumetric precision.

Complete services right from Design, Engineering, Manufacturing, Quality, Testing, Field Services, Spare part supply, Troubleshooting, Retrofitting, Reliability Improvement Programs, Reverse engineering (Re-engineering), Installation, Commissioning and Training is provided.

SERVICES

- Blow Out Preventers

- Workover : Mechanical & Hydraulic

- Drilling : Annular, Ram Preventers, Spherical

- Risers | DSAs | Spools | Els | Blinds | Tees | Slip on Casing Connector

- Manifolds

- Drill String Products

- Chokes | Valves

- Geothermal Wellhead | Trees Wellhead & Christmas Tree Equipment

MANUFACTURING OPTIONS:

- Manufactured to meet client project specification and international codes and standards such as API, ASME

- Most robust fluid ends and power ends in the industry

- Packaging option available with Motors (Fixed and VFD) and Engines

- Transmission through gearbox/V belt drives

- Lubricators

- Dampeners and PSV and robust plunger packing system

Vendor managed inventory

Leave a CommentVENDOR MANAGED INVENTORY

SUPPLY OF SPARE PARTS FOR ALL OEM’S OF CENTRIFUGAL PUMPS AND TURBO MACHINERY

Supply of spare parts for all OEM’s of Centrifugal pumps, Oil field equipment and Turbo machinery thereby enabling Operators to maintain an agreed inventory of material through artificial intelligence and business practices used worldwide ,thereby drastically reducing spends on inventory.

Major benefits for operators include:

Condition monitoring

Leave a CommentCONDITION MONITORING

SUPPORT WITH WIRELESS CONDITION MONITORING SYSTEM TO ENHANCE PLANT RELIABILITY

Services and repairs

Leave a CommentSERVICES AND REPAIRS

Supporting clients with specialists in Pumps, Compressors, Turbo machinery, Wellhead and Oilfield equipment (Workover and Maintenance Projects) to support with specialist field services and workshop based repairs and overhauls.

The team can support with all across brand OEM repairs and overhauls including troubleshooting, Installation and Commissioning of major equipment.

Highly experienced Field Service staff to support with

Reverse Engineering

Leave a CommentReverse Engineering

Partnered to support with Re-engineering and Reverse engineering

Re-engineering and Reverse engineering, manufacturing and testing of OEM equivalent spare parts for all OEMS of pumps, wellhead, oil field equipment and turbomachinery. This is carried out through advanced techniques such as 3D printing or conventional casting/investment casting.

Advanced engineering is carried out to improve reliability for low reliability equipment and improve performance where performance improvement is required.

The reverse engineering process enables major advantages to client and operators

Engineering

Leave a CommentEngineering

Partnered to support with Complete Engineering support

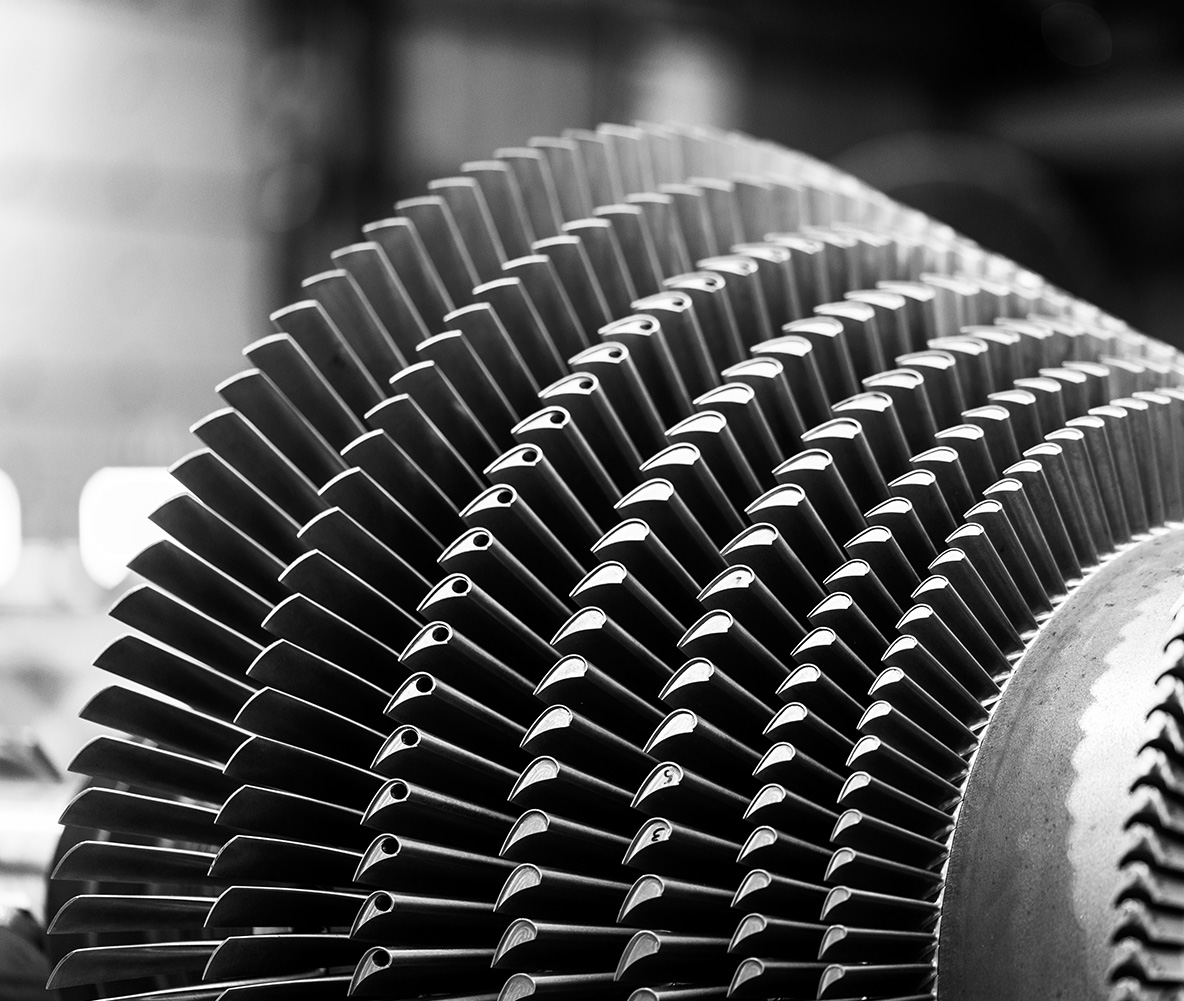

Turbomachinery

Leave a CommentTurbomachinery

Independent service provider who support with partners in Reverse engineering of spares, Service and Repairs, manufacturing of spares parts, engineering and numerical analysis for Centrifugal Compressors, Gas & Steam Turbines.

Support with Complete Overhauls, , refurbishment and retrofits, reverse engineering of spares for all type of Turbomachinery. Manufacturing and workshop locations worldwide across North, Central and South America, Europe, Middle east and far east supporting Operators across the globe.

Pump

Leave a CommentPump

Independent service provider with manufacturing and partner workshop facilities in India and across the globe. Design, Engineering, Manufacturing, Reverse and Re-Engineering, Quality, Testing, Field Services, Spare part supply and Reliability Improvement Programs catering to all OEM’s.

Centif associate with Partners from across the globe to provide Original Equipment Manufacturer independent services on Centrifugal pumps and all other types of pumps.

Complete services right from Design, Engineering, Manufacturing, Quality, Testing, Field Services, Spare part supply, Reliability Improvement Programs, Reverse engineering (Re-engineering) and training is provided.